To install a floor transition strip, first measure and cut the strip to fit the length of the doorway. Then, secure the strip to the floor using adhesive or screws, ensuring it is flush with both flooring surfaces.

Now, let’s dive into the details of how to install a floor transition strip. Flooring transitions are installed to bridge the gap between two different types of flooring, ensuring a smooth and seamless transition between rooms or areas. Whether you are transitioning from hardwood to carpet, tile to laminate, or any other combination, using a transition strip can provide a professional and finished look to your flooring project.

In this guide, we will walk you through the step-by-step process of installing a floor transition strip. With the right tools and materials, you can easily achieve a clean and professional finish that enhances the overall appearance of your flooring. So, without further ado, let’s get started with the installation process.

1. Wood Transition Strips

Advantages

Wood transition strips offer several advantages when it comes to installing floor transitions. These advantages include:

- Easy Installation: Wood transition strips are relatively easy to install, making them a popular choice among DIY enthusiasts. With basic tools and a few simple steps, you can have a professionally finished transition between different types of flooring.

- Wide Range of Options: Wood transition strips come in various finishes, colors, and designs, allowing you to choose one that best complements your existing flooring. Whether you have hardwood, laminate, or tile floors, you can find a wood transition strip that seamlessly blends in with your décor.

- Durable and Long-Lasting: Wood transition strips are known for their durability. Made from solid wood materials such as oak, birch, or maple, these strips can withstand heavy foot traffic and last for years without showing signs of wear and tear.

- Smooth and Safe Transitions: One of the primary functions of a floor transition strip is to provide a smooth and safe transition between two different types of flooring. Wood transition strips excel at this, creating a seamless transition while reducing the risk of tripping or stumbling over uneven surfaces.

- Enhances Aesthetics: In addition to their functional benefits, wood transition strips also enhance the aesthetics of your space. By creating a seamless transition between different flooring materials, these strips contribute to a cohesive and visually appealing overall look.

Disadvantages

While wood transition strips offer numerous advantages, it’s important to also consider their potential disadvantages:

- Maintenance: Wood transition strips require regular maintenance to keep them looking their best. This may involve periodic cleaning, refinishing, or resealing to preserve their appearance and protect them from moisture or stains.

- Potential for Damage: Since wood is a natural material, it can be susceptible to damage from moisture, temperature changes, or heavy impacts. It’s essential to take precautions and protect wood transition strips from these potential hazards to ensure their longevity.

- Cost: Compared to other types of floor transition strips, wood transition strips can be relatively more expensive. However, the cost can vary depending on the type of wood and the design chosen. It’s important to weigh the cost against the durability and aesthetic benefits they offer.

2. Metal Transition Strips

If you are considering adding a touch of elegance and durability to your flooring project, metal transition strips might be the perfect choice for you. These strips not only enhance the visual appeal of your floors but also provide a smooth and safe transition between different flooring materials. In this section, we will discuss the advantages and disadvantages of using metal transition strips.

Advantages

Metal transition strips offer several benefits that make them a popular choice among homeowners and flooring professionals alike:

- Durability: Metal transition strips are known for their exceptional durability. They are designed to withstand heavy foot traffic and are resistant to scratches, dents, and other types of damage.

- Aesthetic appeal: Metal transition strips add a touch of sophistication to any space. With various finishes available, including chrome, brass, and stainless steel, you can easily find a style that complements your existing flooring and decor.

- Smooth transition: One of the primary purposes of transition strips is to provide a seamless transition between different flooring surfaces. Metal strips accomplish this seamlessly, ensuring a smooth surface that you can walk, wheel, or slide over effortlessly.

- Easy installation: Metal transition strips are relatively easy to install, making them a convenient choice for DIY enthusiasts. Most strips come with pre-drilled holes and mounting hardware, simplifying the installation process.

- Cleaning: When it comes to maintenance, metal transition strips are incredibly easy to clean. They can be wiped down with a damp cloth or simply vacuumed alongside the rest of the flooring.

Disadvantages

While metal transition strips offer numerous advantages, it’s important to consider the potential drawbacks:

- Cost: Metal transition strips can be more expensive than other options available in the market. However, the durability and aesthetic appeal they offer make them a worthwhile investment in the long run.

- Noise: Metal transition strips may produce noise when walked over, especially if they are installed on hollow or uneven subfloors. To minimize this issue, it’s recommended to ensure proper installation and use additional soundproofing materials if needed.

- Temperature transfer: Metal is an excellent conductor of heat and cold, which means that metal transition strips may transfer the temperature from one area to another. However, this can be mitigated by using insulated underlayments or rugs.

3. Rubber Transition Strips

Rubber transition strips are a popular choice when it comes to installing floor transition strips. These strips are made from durable rubber materials that offer several advantages. However, they also come with their fair share of disadvantages. In this section, we will explore the advantages and disadvantages of using rubber transition strips for your flooring project.

Advantages

- Durability: Rubber transition strips are highly durable, making them an ideal choice for high-traffic areas. They can withstand heavy foot traffic, the movement of heavy furniture, and other wear and tear, ensuring they last for years.

- Flexibility: Unlike other transition strip materials, rubber strips offer flexibility. This means they can easily conform to uneven surfaces, making them suitable for flooring projects where there may be height differences or irregularities.

- Water-resistant: Rubber transition strips are resistant to water and moisture, making them suitable for areas prone to spills or high moisture levels, such as kitchens, bathrooms, and laundry rooms. The water-resistant properties also make them easy to clean and maintain.

Disadvantages

- Appearance: One of the main disadvantages of rubber transition strips is their appearance. While they come in a variety of colors and designs, they may not offer the same aesthetic appeal as other materials like wood or metal. However, if functionality is your priority, this may not be a major concern.

- Installation: Installing rubber transition strips can be slightly more challenging compared to other materials. They often require adhesive or glue for proper installation, which may require additional time and effort. It’s important to follow the manufacturer’s instructions carefully to ensure a secure installation.

- Cost: Rubber transition strips can be more expensive compared to other types of transition strips. Although they offer durability and longevity, the initial cost may be higher. However, considering their long lifespan and low maintenance requirements, they can be a worthwhile investment in the long run.

Despite its disadvantages, rubber transition strips are a versatile and practical choice for many flooring projects. Consider the specific needs of your space and weigh the advantages and disadvantages to determine if rubber transition strips are the right fit for your project.

1. Measuring Tape

Explanation of Use

The measuring tape is an essential tool when it comes to installing a floor transition strip. This simple yet versatile tool allows you to accurately measure the length, width, and height of the transition area, ensuring a flawless installation. By using a measuring tape, you can determine the exact size of the strip needed, helping you avoid any unnecessary cutting, adjustments, or gaps.

Measuring Length

To measure the length of the transition area, start by extending the tape from one end to the other. Make sure the tape is straight and aligns with the edges of the flooring. Take note of the measurement, and write it down for reference.

Measuring Width

Next, you’ll need to measure the width of the transition area. Place the tape perpendicular to the length measurement, ensuring it spans across the entire width of the transition. Once again, record the measurement for future use.

Measuring Height

In addition to length and width, you may also need to measure the height of the transition area. This is particularly important if the strip needs to match the level of different types of flooring. To measure the height, align the tape vertically along the edge of the lower flooring and extend it until it reaches the top of the higher flooring. Take note of this measurement as well.

By accurately measuring the length, width, and height of the transition area, you can ensure that the floor transition strip fits perfectly, providing a seamless and professional finish. Remember to double-check your measurements before making any cuts or purchases to avoid any costly mistakes.

So, grab your measuring tape and get ready to install your floor transition strip with precision and confidence.

2. Miter Saw

In order to properly install a floor transition strip, you will need a miter saw. This powerful tool is essential for achieving clean and accurate cuts, ensuring a seamless transition between flooring materials. Below, we will take a closer look at the miter saw and its uses in the installation process.

Explanation of use

The miter saw is a specialized power tool designed to make precise angled cuts. It features a circular blade mounted on a hinged arm, which can be pivoted to different angles for both miter and bevel cuts. This flexibility allows you to create clean and accurate joints, ensuring a professional finish for your floor transition strip.

The miter saw is particularly useful when installing floor transition strips that require angled cuts, such as those used to bridge the gap between two different flooring materials. It allows you to make accurate cuts at various angles, such as 45 degrees for a typical 90-degree corner or a custom angle to match the specific configuration of your flooring.

By using a miter saw, you can achieve precise cuts with minimal effort, saving time and ensuring a seamless transition between flooring materials. This tool is a must-have for any DIY enthusiast or professional installer looking to achieve a flawless finished result.

Examples of use

Here are a few examples of how a miter saw can be used in the installation of a floor transition strip:

- Cutting baseboards: Before installing the transition strip, it’s important to remove any existing baseboards that may interfere with the installation. A miter saw can be used to make precise cuts on the baseboards, ensuring a seamless fit between the transition strip and the wall.

- Creating angled cuts: If your flooring materials meet at an angle other than 90 degrees, a miter saw allows you to make custom angled cuts on the transition strip. This ensures a perfect fit and a smooth transition between the two flooring materials.

- Making straight cuts: Even if your flooring materials meet at a 90-degree angle, a miter saw can still be useful for making clean and straight cuts on the transition strip. This ensures a professional-looking finish and eliminates any gaps or unevenness.

Overall, the miter saw is an indispensable tool when it comes to installing a floor transition strip. From making angled cuts to creating precise joints, this versatile power tool ensures a seamless transition between flooring materials, enhancing the overall appearance of your space.

3. Adhesive

When it comes to installing a floor transition strip, choosing the right adhesive is crucial. The adhesive plays a key role in ensuring that the transition strip stays in place and provides a seamless connection between two different types of flooring. In this section, we will delve into the explanation of use and the types of adhesives that are commonly used for floor transition strip installations.

Explanation of use

Before deciding on the type of adhesive to use, it is important to understand the purpose and benefits of using adhesive for floor transition strips. Adhesives are designed to create a strong bond between the transition strip and the underlying floor surface. They create a durable connection that prevents the transition strip from moving, lifting, or becoming loose over time. Additionally, adhesives help to fill any gaps between the strip and the floor, ensuring a smooth and level transition between the two surfaces.

Types of adhesives

There are several types of adhesives available for floor transition strip installations, each with its own unique characteristics and suitability for different flooring materials. Here are the most commonly used types:

1. Construction adhesive

Construction adhesive is a versatile and strong adhesive that is commonly used for floor transition strips. It can bond a wide range of materials together, including wood, concrete, and tile. This adhesive is typically applied using a caulking gun, making it easy to control and apply precisely where needed. Construction adhesive provides a long-lasting bond that can withstand heavy foot traffic and changes in temperature.

2. Epoxy adhesive

Epoxy adhesive is a two-part adhesive that offers a strong and durable bond. It consists of a resin and a hardener that need to be mixed together before application. Epoxy adhesive is known for its high strength and ability to bond to various materials. It is particularly suitable for transitions between different types of hard surfaces, such as tile to concrete or wood. Epoxy adhesive is resistant to water, chemicals, and extreme temperatures, making it a reliable choice for areas prone to moisture or heat.

3. Carpet tape

Carpet tape is a double-sided adhesive tape that is specifically designed for securing transition strips with carpeted areas. It provides a quick and easy solution for attaching the strip to the carpet, ensuring a smooth and secure transition. Carpet tape is typically applied by peeling off the backing and sticking it directly to the strip and the carpet surface. It is important to choose a high-quality carpet tape that is strong enough to hold the strip firmly in place, especially in high-traffic areas.

Before applying any adhesive, it is important to read and follow the manufacturer’s instructions. This ensures that you use the adhesive correctly and achieve the best results. It is also advisable to clean and prepare the surfaces to be bonded, removing any dust, dirt, or debris that can affect the adhesive’s performance.

Now that you have a better understanding of the role and types of adhesives used for floor transition strip installations, you can confidently choose the adhesive that best matches your flooring materials and installation needs. The right adhesive will ensure a secure, long-lasting, and visually appealing transition between different flooring surfaces in your home or commercial space.

4. Drill

Explanation of use

Using a drill is an essential step when installing a floor transition strip. It allows you to create pilot holes for screws, ensuring a secure and long-lasting installation. Whether you are installing a transition strip between different types of flooring materials or covering gaps between two rooms, a drill makes the process much easier.

How to choose the right drill bit

Choosing the right drill bit is crucial for a successful installation. The drill bit you select should be compatible with the material of your transition strip and the surface it will be installed on. Here are some factors to consider when choosing a drill bit:

- Material: Determine whether your transition strip is made of wood, metal, or another material. Different materials require different drill bits.

- Size of the screw: The drill bit should be slightly smaller in diameter than the screw you will be using. This ensures a snug fit and prevents the wood from splitting.

- Type of surface: Consider the type of surface you will be drilling into. If it’s a hard material like concrete or tile, you will need a masonry drill bit. For wooden or plastic surfaces, a standard drill bit will suffice.

In addition to choosing the right drill bit, it’s important to have a good quality drill that is suitable for the task. Investing in a reliable drill with variable speed settings and a comfortable grip will make the drilling process smoother and more efficient.

Once you have the appropriate drill and drill bit, follow these steps for drilling during the floor transition strip installation:

- Mark the drilling spots: Use a pencil or a marker to mark the spots where you will be drilling the pilot holes. These spots should align with the pre-drilled holes on the transition strip.

- Secure the transition strip: Hold the transition strip firmly in place, ensuring it is aligned correctly with the floor edges. Use clamps or masking tape to keep it secure.

- Start drilling: With the drill in the forward position and at a low speed, position the drill bit on one of the marked spots and apply gentle pressure. Begin drilling slowly, keeping the drill perpendicular to the surface.

- Drill to the appropriate depth: Drill to a depth slightly shorter than the length of the screws you will be using. This will prevent the screws from protruding through the strip.

- Repeat the process: Repeat the drilling process for each marked spot, ensuring the holes are evenly spaced along the length of the transition strip.

Remember to wear protective goggles and work in a well-ventilated area when using a drill. Once all the pilot holes are drilled, you can proceed with the installation of the floor transition strip by securing it with screws. A properly drilled transition strip will provide stability and prevent tripping hazards between flooring surfaces.

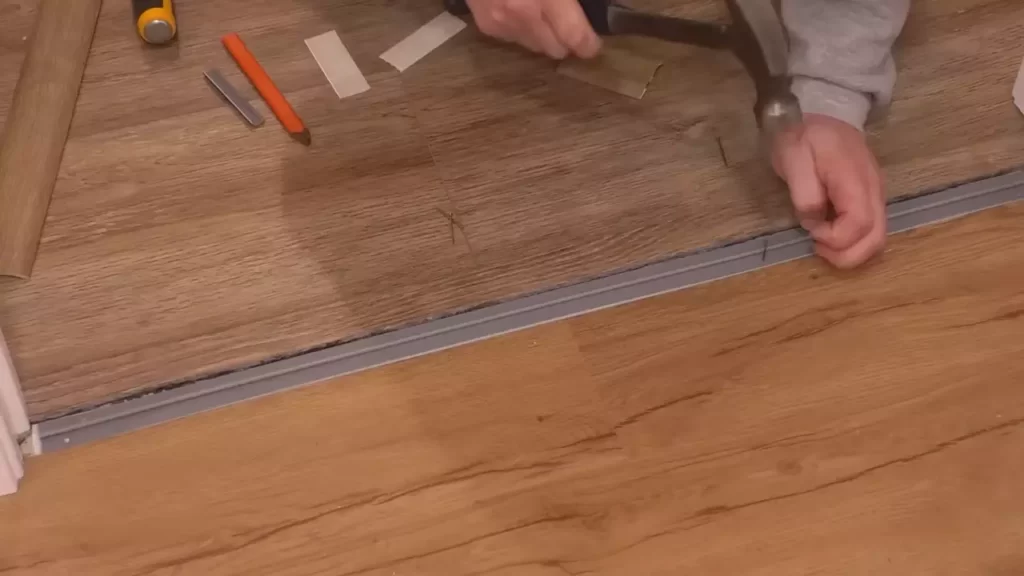

5. Hammer

When it comes to installing a floor transition strip, one tool that you’ll definitely need is a hammer. The hammer is an essential tool for securing the transition strip in place and ensuring a solid and sturdy installation. In this section, we’ll explore the explanation of use for the hammer and provide some tips to help you make the most of this tool.

Explanation of Use

The primary use of a hammer in the installation of a floor transition strip is to drive nails or brads through the strip and into the subfloor. This helps to secure the strip in place and prevent any movement or shifting over time. A hammer with a claw is particularly useful as it allows you to remove any nails that may need adjusting or replacing.

Using a hammer correctly is crucial to a successful installation. Here are some tips to keep in mind:

- Choose the right hammer: It is important to select a hammer that is well-suited for the job. A standard claw hammer with a comfortable grip is usually the best choice for installing a floor transition strip.

- Position the strip: Before using the hammer, ensure that the floor transition strip is in the desired position and aligned properly with the adjoining flooring materials.

- Hold the hammer correctly: For a controlled strike, grip the hammer firmly near the base of the handle.

- Apply consistent force: Use a smooth and consistent hammering motion to drive the nails or brads through the strip and into the subfloor. Avoid striking the hammer with excessive force, as this may damage the strip or the surrounding flooring materials.

- Inspect the result: After hammering the nails or brads, ensure that the strip is securely attached to the subfloor and that there are no visible gaps or loose sections.

By following these tips, you can ensure that the use of the hammer in installing the floor transition strip is effective and efficient.

1. Measuring The Gap

Accurately measuring the gap between two flooring types is crucial when installing a floor transition strip. This step ensures a seamless integration of the transition strip and prevents any trip hazards or unsightly gaps. Let’s dive into the explanation of how to measure the gap with precision.

Explanation of how to accurately measure the gap:

Before you start measuring, it’s essential to have the right tools on hand. Grab a measuring tape, a pencil, and maybe a scrap piece of wood to help support the tape.

Here’s a step-by-step guide on how to accurately measure the gap:

- Start by identifying the two flooring surfaces between which you’ll be installing the transition strip.

- Position yourself at the edge where the transition strip will be placed, ensuring you have proper lighting to clearly see the gap.

- Place the measuring tape’s end firmly against one side of the gap and extend it across to the other side.

- Read the measurement on the tape, ensuring it is as precise as possible. Round the measurement to the nearest 1/8 inch for better accuracy.

- Repeat the measuring process in multiple spots along the gap to account for any irregularities or differences in width.

- Take note of the largest measurement obtained; this will be the width of the transition strip you need to install.

If you encounter any obstacles or obstructions like baseboards or door frames, make sure to measure the gap from the edges closest to the flooring, excluding those objects. This way, your transition strip will fit seamlessly across the gap.

By accurately measuring the gap, you are setting yourself up for a successful floor transition strip installation. Now that you have the width measurement, you can move on to selecting the appropriate transition strip and confidently proceed with the installation process.

2. Choosing The Right Transition Strip

Factors to Consider when Selecting the Appropriate Strip

Choosing the right transition strip is crucial to achieving a seamless and professional-looking flooring installation. There are a few key factors to consider when making this decision.

1. Height and Width

One of the first things to consider is the height and width of the transition strip. This is important to ensure an even and smooth transition between different floor types. Measure the height difference between the two floors and choose a strip that will accommodate this gap. Additionally, consider the width of the strip to ensure it is wide enough to cover the necessary area.

2. Floor Type

The type of flooring you have will also play a role in determining the right transition strip. Different materials and thicknesses require different types of strips. For example, if you are transitioning between carpet and hardwood floors, a strip with a transition lip may be necessary to securely hold the carpet in place. Consider the specific needs of your flooring materials when selecting a strip.

3. Style and Finish

Transition strips come in a variety of styles and finishes to match your overall decor. Consider the overall aesthetic of your space and choose a strip that complements the existing flooring and decor. Whether you prefer a sleek metal finish or a matching wood grain, there is a strip available to suit your style.

4. Installation Method

Another important factor to consider is the installation method of the transition strip. Some strips require adhesives or screws to secure them in place, while others are designed to simply snap into position. Consider your skill level and the specific requirements of your flooring installation when selecting a strip with the appropriate installation method.

5. Durability and Maintenance

Lastly, consider the durability and maintenance requirements of the transition strip. Look for a strip that is made from high-quality materials and is built to withstand daily wear and tear. Additionally, choose a strip that is easy to clean and maintain, ensuring it will continue to look great over time.

By considering these factors when selecting the appropriate transition strip, you can ensure a seamless and professional-looking flooring installation that adds both functionality and style to your space.

3. Preparing The Subfloor

Before installing a floor transition strip, it is crucial to prepare the subfloor properly. By ensuring a clean and well-prepared subfloor, you can guarantee the longevity and durability of your transition strip installation. Let’s explore how to clean and ensure the subfloor is ready for installation.

How to clean and ensure the subfloor is ready for installation

- Remove any existing flooring: Start by removing any existing flooring materials, such as carpeting, vinyl, or laminate. Ensure that the subfloor is completely exposed.

- Clear the subfloor of debris: Sweep or vacuum the subfloor to eliminate any dust, dirt, or loose particles. It’s important to create a clean surface for the transition strip to adhere to.

- Check for damage: Inspect the subfloor for any signs of damage, such as cracks, rot, or unevenness. Address any issues before proceeding further.

- Repair or replace damaged areas: If you encounter any damaged areas on the subfloor, now is the time to repair or replace them. Fill cracks with appropriate filler, replace rotting wood, and level any uneven spots.

- Ensure subfloor moisture levels are within the acceptable range: High moisture can cause issues with flooring installations. Use a moisture meter to test the moisture levels of the subfloor. Ideally, the moisture content should be below 12%.

- Moisture barrier installation (if necessary): If the moisture levels are high, consider installing a moisture barrier before proceeding. Follow the manufacturer’s instructions to properly install the moisture barrier.

Tools needed for preparation

Preparing the subfloor requires the use of specific tools. Make sure you have the following tools ready before you begin:

| Tools | Description |

|---|---|

| Utility knife | For cutting and trimming flooring materials. |

| Hammer | For removing nails or fixing minor subfloor issues. |

| Screwdriver | For removing screws or fixing minor subfloor issues. |

| Vacuum cleaner or broom | To remove debris and ensure a clean subfloor. |

| Moisture meter | To check the moisture levels of the subfloor. |

| Floor filler | For repairing cracks or small damages on the subfloor. |

| Moisture barrier | If necessary, for installing a moisture barrier. |

Make sure you have all these tools on hand to ensure a smooth and hassle-free preparation process.

1. Cutting The Transition Strip To Size

One important step in installing a floor transition strip is cutting it to the right size. This ensures that the strip fits perfectly and provides a smooth transition between different flooring types. In this step-by-step guide, we will walk you through the process of measuring and cutting the transition strip to ensure a professional-looking installation.

Step-by-Step Guide on Measuring and Cutting the Strip

Follow these simple steps to measure and cut your transition strip accurately:

- Measure the Gap: Start by measuring the gap between the two flooring surfaces where you want to install the transition strip. Use a tape measure to get an accurate measurement. Write down the measurement so that you can refer to it when cutting the strip.

- Mark the Strip: Next, take your transition strip and place it on a flat surface. Use a pencil or marker to mark the length based on the measurement you took in the previous step. Make sure the mark is clear and easy to see.

- Secure the Strip: To ensure stability while cutting, you can secure the transition strip using clamps or a vice. This will help prevent any movement or slipping, resulting in a cleaner cut.

- Cut the Strip: Once the strip is secured, use a fine-toothed saw or a miter saw to cut along the marked line. Take your time and make slow, precise cuts to ensure a clean and accurate cut. Double-check the measurement before finalizing the cut to avoid any mistakes.

- Test the Fit: After cutting the strip, test its fit by placing it in the gap between the flooring surfaces. Make any necessary adjustments if the strip is too long or too short. It should fit snugly and provide a smooth transition between the two surfaces.

By following these steps, you can easily cut a transition strip to the right size and achieve a seamless transition between different flooring types. Remember to take accurate measurements, make precise cuts, and test the fit before finalizing the installation. With a bit of patience and attention to detail, you’ll have a professional-looking floor transition strip in no time!

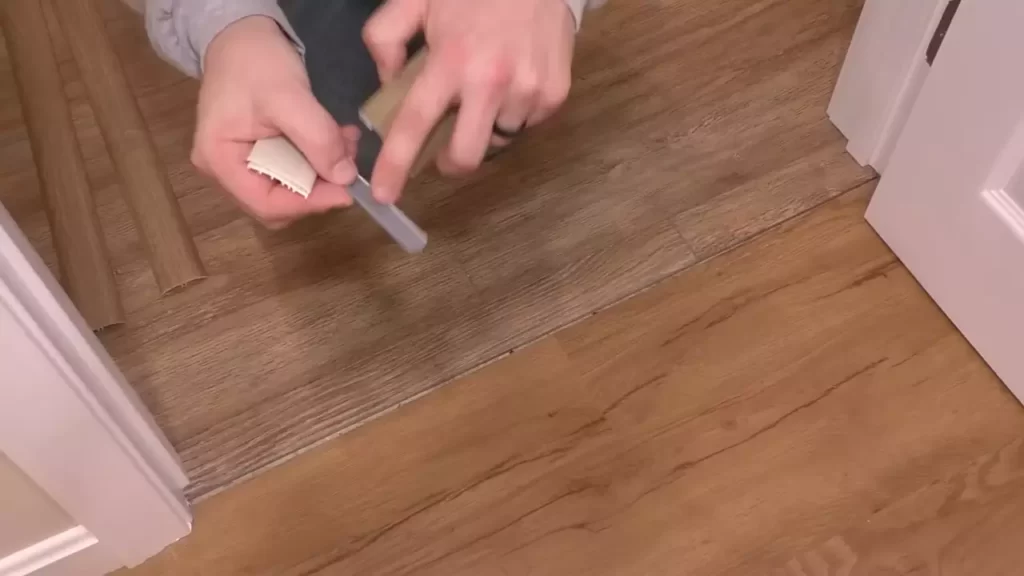

2. Applying Adhesive

How to apply adhesive to the strip and subfloor

Once you have measured and cut your floor transition strip to fit, the next step is applying adhesive. Applying adhesive properly is crucial to ensure a secure and long-lasting installation. Here’s a step-by-step guide on how to apply adhesive to both the strip and subfloor.

1. Prepare the surface: Before applying adhesive, make sure that both the floor transition strip and the subfloor are clean and free from any dust, debris, or grease. A clean surface will allow the adhesive to bond effectively.

2. Choose the right adhesive: There are different types of adhesives available for floor transition strips, including liquid adhesive and adhesive tape. Choose an adhesive that is designed for your specific strip and subfloor materials. Refer to the manufacturer’s instructions for guidance.

3. Apply adhesive to the strip: Depending on the type of adhesive you are using, apply it either directly to the backside of the strip or to the subfloor. If using liquid adhesive, follow the manufacturer’s instructions for application techniques. Spread the adhesive evenly, ensuring that it covers the entire backside of the strip.

4. Apply adhesive to the subfloor: If you have chosen to apply adhesive directly to the subfloor, use a trowel or putty knife to spread a thin layer of adhesive. Ensure that the adhesive covers the entire area where the strip will be placed.

5. Align and press: Once the adhesive is applied, carefully align the floor transition strip with the edge of the subfloor. Make sure it is positioned correctly before pressing it firmly into place. Applying pressure will help the adhesive bond effectively.

Tips for proper application

To ensure a successful installation and a professional-looking result, here are some tips for properly applying adhesive to your floor transition strip and subfloor.

– Follow manufacturer’s instructions: Adhesive products may have specific instructions for application, drying time, and other important details. Always refer to the manufacturer’s guidelines to achieve the best results.

– Use the right amount of adhesive: Applying too much adhesive can result in seepage, while applying too little may not provide sufficient bonding. A thin, even layer of adhesive is usually recommended for proper adhesion.

– Allow sufficient drying time: It is important to allow the adhesive to fully dry and cure before subjecting it to any foot traffic or stress. Follow the manufacturer’s recommended drying time for optimal results.

– Check and adjust alignment: Before the adhesive sets, double-check the alignment of the strip to ensure it is straight and even. Adjust if necessary before the adhesive dries completely.

– Clean up excess adhesive: Wipe away any excess adhesive that may have squeezed out from under the strip during installation. A damp cloth can be used to clean up adhesive residue.

By following these steps and tips, you can ensure a proper application of adhesive for your floor transition strip. A secure and well-installed strip will not only enhance the appearance of your flooring but also provide a smooth transition between different types of flooring materials.

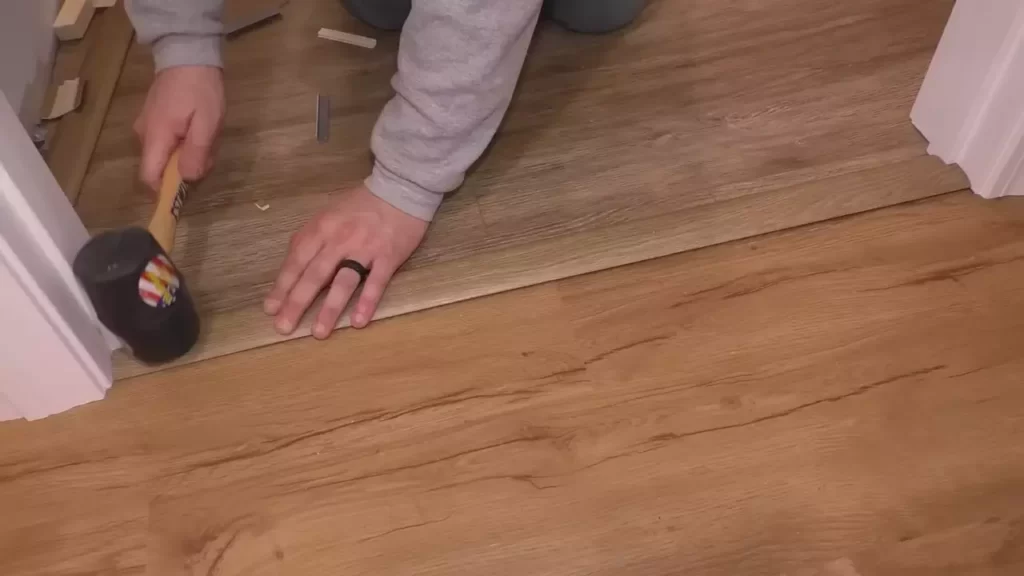

3. Securing The Transition Strip

After successfully cutting and fitting the transition strip into place, the next crucial step is securing it to ensure it stays in position and functions optimally. There are a variety of methods you can use to secure the strip, depending on the type of flooring materials and the specific requirements of your installation project.

Step-by-step guide on how to secure the strip in place

- Clean the installation area: Before securing the transition strip, make sure the installation area is clean and free from any debris or dust. This will ensure a tight and secure fit.

- Attach adhesive: Apply a suitable adhesive onto the subfloor or the bottom of the transition strip. Ensure to read the manufacturer’s instructions and choose an adhesive that is compatible with the flooring materials you are working with.

- Press the strip firmly: Carefully position the transition strip over the transition area and press it firmly into place. Apply even pressure along the entire length of the strip to ensure proper adhesion.

- Secure with screws or nails: For added stability, you may choose to further secure the transition strip with screws or nails. This is particularly beneficial for high-traffic areas or if the adhesive alone is not sufficient.

- Fill any gaps or holes: If there are any gaps or holes between the strip and the surrounding flooring, fill them in with a suitable filler material to prevent tripping hazards and to create a smooth transition.

Different methods for securing the strip

The method you choose to secure the transition strip will depend on the specific requirements of your installation project. Here are some common methods:

| Method | Description |

|---|---|

| Adhesive | Using adhesive is a popular and effective method for securing transition strips. It provides a strong bond between the strip and the subfloor, ensuring stability and longevity. |

| Screws | Securing the strip with screws provides additional strength and durability, especially for heavy traffic areas. It is important to choose the appropriate screw size and type for your flooring materials. |

| Nails | Nails are another option for securing the transition strip. However, nails may not provide as strong of a bond as screws, so they are typically better suited for lighter use areas. |

Ultimately, the method you choose will depend on factors such as the type of flooring materials, the traffic intensity of the area, and personal preference. It is always recommended to follow the manufacturer’s instructions and consult with a professional if you are unsure about the best method for securing the transition strip for your specific installation project.

1. Cleaning And Maintaining The Transition Strip

Proper cleaning and maintenance of the transition strip is essential to keep it in good condition and prolong its lifespan. By following these tips, you can ensure that your transition strip remains clean and functional for years to come.

Tips for keeping the strip clean and in good condition

Regular cleaning and maintenance of the transition strip will help prevent dirt build-up, scratches, and other damages. Here are some simple yet effective tips to keep your strip clean and in optimal condition:

- Remove dust and debris: Start by removing any loose dirt, dust, or debris from the strip. You can use a soft-bristle brush or a vacuum cleaner to gently sweep away the particles.

- Wipe with a damp cloth: Dampen a cloth or sponge with mild soap and water solution. Gently wipe down the transition strip to remove any residual dirt or stains. Avoid using harsh chemicals that may damage the strip.

- Dry thoroughly: After cleaning, make sure to dry the transition strip thoroughly. Excess moisture can warp or damage the strip, so use a dry cloth or allow it to air dry completely.

- Avoid excessive moisture: To prevent water damage, avoid excessive moisture on the transition strip. Wipe up any spills or liquid immediately and ensure the strip is dry.

- Protect from scratches: Place protective pads or felt under heavy furniture or objects to prevent scratches or dents on the transition strip. Regularly check and replace any worn-out pads to maintain the strip’s integrity.

Ongoing maintenance and inspections

In addition to regular cleaning, ongoing maintenance and inspections can help identify any issues early and prevent further damage. Consider the following:

- Inspect for wear and tear: Regularly inspect the transition strip for any signs of wear, such as cracks, chips, or loose edges. Address any issues promptly to prevent further damage.

- Tighten loose screws or nails: If the transition strip is secured with screws or nails, check them periodically and tighten if necessary. Loose fasteners can cause the strip to shift or become unstable.

- Reapply adhesive if needed: If your transition strip is adhesive-backed and you notice it starting to peel or come loose, consider reapplying adhesive according to the manufacturer’s instructions.

- Seek professional help if required: For extensive damage or if you’re unsure about the best course of action, it’s always advisable to consult a professional flooring installer or contractor.

By following these cleaning and maintenance tips, you can ensure that your transition strip remains clean, secure, and visually appealing. Regular upkeep will not only prolong its lifespan but also contribute to the overall beauty and functionality of your flooring transition.

2. Covering Gaps And Adjustments

After successfully installing a floor transition strip, it’s important to address any gaps or adjustments that may arise. While most installations go smoothly, it’s not uncommon to encounter small gaps or minor adjustments that require attention. By following a few simple steps, you can ensure that your transition strip fits seamlessly and provides a polished finish to your flooring project.

How to address any gaps or adjustments that may arise after installation

If you notice gaps or adjustments after installing your floor transition strip, don’t worry. It’s a common occurrence and can easily be resolved. Here’s how you can address these issues:

- Measure the gap: Use a tape measure or ruler to determine the size of the gap or adjustment. It’s crucial to have accurate measurements before proceeding to the next step.

- Choose the appropriate filler: Depending on the size of the gap, you may need to use a filler material. Options such as wood filler, silicone caulk, or epoxy putty can be suitable, depending on the type of transition strip and the surrounding materials.

- Prepare the surface: Before applying any filler, make sure the area is clean and free of debris. Use a vacuum or a damp cloth to remove any dust or dirt that may affect the adhesion of the filler.

- Apply the filler: Following the manufacturer’s instructions, apply the selected filler material into the gap. Smooth it out using a putty knife or a plastic spatula until the filler is level with the surrounding surface.

- Allow for drying or curing time: Different filler materials require varying amounts of time to dry or cure completely. Be patient and follow the instructions provided by the manufacturer to ensure the best results.

- Finishing touches: Once the filler has dried or cured, you can apply a finish to match the surrounding flooring. Options include staining, painting, or applying a clear sealant. Consult with a professional or refer to the manufacturer’s recommendations for the most suitable finishing technique.

Remember, addressing any gaps or adjustments promptly will not only enhance the aesthetic appeal of your floor transition strip but also prevent potential tripping hazards and maintain the longevity of your flooring installation.

Example:

Let’s say you’ve installed a wood transition strip between a hardwood floor and a tile surface. After installation, you notice a small gap along one side. Following the steps outlined above, you measure the gap and determine it to be 1/8 inch wide. You choose a wood filler that matches the color of the transition strip and proceeds to fill the gap using a putty knife. After allowing the filler to dry for the recommended time, you lightly sand it to ensure a smooth finish. Finally, you apply a clear sealant to protect the filler and blend it with the surrounding hardwood floor. Voila! Your transition strip now seamlessly bridges the gap and provides a polished transition between the two different flooring materials.

3. Final Inspection And Use

Steps to take to ensure the transition strip is installed correctly and ready for use

Now that you have successfully installed your floor transition strip, it’s time for the final inspection to ensure everything is in place and ready for use. Following these simple steps will ensure that your transition strip is installed correctly and meets your requirements.

Inspect the alignment of the transition strip

The first thing you want to check is the alignment of the transition strip. Ensure that it is precisely positioned between the two flooring surfaces, creating a smooth and seamless transition. Use a level or straight edge to check that the strip is perfectly aligned and make any necessary adjustments. A misaligned transition strip can cause tripping hazards and an unpleasant aesthetic appearance.

Check for any gaps or loose sections

Next, carefully inspect the entire length of the transition strip for any gaps or loose sections. Gaps can lead to dirt and debris accumulation, while loose sections can cause potential tripping hazards. If you notice any gaps or loose sections, apply an appropriate adhesive or use screws/nails to secure the strip firmly in place. This will ensure the longevity and stability of the transition strip.

Confirm a secure and flush installation

The transition strip should be securely attached to the subfloor and the adjacent flooring surfaces. Check for any areas where the strip may be lifting or not sitting flush against the floor. If you find any such areas, use additional adhesive or fasteners to ensure a secure and smooth installation. This will prevent any unnecessary movement or shifting of the transition strip during regular use.

Test the transition strip for functionality

The final step in the inspection process is to test the functionality of the transition strip. Walk across the strip to ensure it feels sturdy and does not move or make any creaking sounds. Pay attention to how it feels when transitioning from one flooring surface to another, ensuring a smooth and comfortable experience. Additionally, visually inspect the transition strip to ensure it blends well with the overall aesthetics of your room.

By carefully following these steps during the final inspection, you can ensure that your installed floor transition strip is both visually appealing and functionally sound. Taking the time to perform a thorough inspection will provide you with peace of mind and help maintain the integrity of your flooring for years to come.

Frequently Asked Questions For How To Install A Floor Transition Strip

How Do You Install Floor Transitions?

To install floor transitions, follow these steps:

1. Measure and cut the transition strip to fit the doorway.

2. Clean the floor and remove any debris or adhesive.

3. Apply adhesive to the subfloor and press the transition strip into place.

4. Secure the strip using screws or nails.

5. Allow the adhesive to dry before walking on the transition.

Do You Glue Down Transition Strips?

No, transition strips are not typically glued down. They are designed to fit securely between two flooring surfaces without the need for adhesive. This ensures flexibility and easy removal if necessary.

What Is The Best Adhesive For Floor Transition Strip?

The best adhesive for a floor transition strip is a construction adhesive specifically designed for flooring applications. It ensures a strong and durable bond between the strip and the floor surface.

Where Do You Put Floor Transitions In A Doorway?

Floor transitions in a doorway should be placed where two different types of flooring meet, ensuring a seamless and aesthetic transition between the two. This helps to prevent tripping hazards and creates a smooth flow between rooms.

Conclusion

Installing a floor transition strip is a simple yet effective way to seamlessly bridge the gap between two different flooring materials. By following the step-by-step process outlined in this blog post, you can successfully install a floor transition strip and enhance the overall aesthetic appeal of your home.

Remember to measure accurately, choose the appropriate strip, and secure it firmly to ensure durability and longevity. With this guide, you’ll be able to achieve professional-looking results and enjoy a smooth and stylish transition between your floors.