To install Freon in an AC unit, follow these steps: Turn off the AC unit, locate the service valves, connect the charging hose, open the valve on the refrigerant tank, and slowly add the Freon until the proper pressure is achieved. Installing Freon in an AC unit is a simple process that can be done by following a few steps.

By carefully adhering to the guidelines and taking necessary precautions, you can ensure that your AC unit is properly charged with Freon, allowing it to function efficiently. We will guide you through the process of installing Freon in your AC unit, providing you with a step-by-step approach to achieve optimal results.

Understanding The Basics Of Freon And Ac Units

When it comes to keeping our homes comfortably cool, air conditioning units play a vital role. But have you ever wondered how these AC units actually work? One of the key components responsible for the cooling effect is Freon. In this article, we will delve into the basics of Freon and AC units, exploring the importance of Freon and how it functions to cool our rooms effectively.

Importance of Freon in AC Units

Freon, also known as refrigerant, is a chemical compound that plays a crucial role in AC units. Its primary function is to absorb the heat present in the room and expel it outside, resulting in a cooling effect. Without Freon, an AC unit would not be able to provide the desired coolness and comfort during hot summer days.

It is important to understand that AC units do not consume or deplete Freon during operation. Instead, Freon circulates within a closed loop system, constantly evaporating and condensing to maintain the cooling cycle. This means that if your AC unit is low on Freon, it is an indication of a potential leak and requires immediate attention from a professional technician.

The Role of Freon in Cooling a Room

The role of Freon in cooling a room is fascinating. To simplify the process, let’s break it down into four steps:

- The compressor in the AC unit pressurizes the Freon gas, turning it into a high-pressure, high-temperature gas.

- This hot gas flows through the condenser coils outside the AC unit, where it dissipates heat to the surrounding air, causing the gas to condense into a high-pressure liquid.

- The high-pressure liquid then enters the expansion valve, which reduces its pressure and allows it to expand into a low-pressure liquid. This expansion causes the temperature of the liquid to drop significantly.

- The low-pressure liquid now enters the evaporator coils inside the AC unit, where it absorbs heat from the room, transforming back into a low-pressure gas. This process extracts heat from the air, resulting in a cooler room.

This continuous cycle of pressurizing, condensing, expanding, and evaporating Freon enables the AC unit to cool the room effectively, providing us with a comfortable environment even on scorching summer days.

To ensure optimum performance and longevity of your AC unit, it is essential to have it regularly maintained and checked for Freon levels by a qualified technician. Detecting and rectifying Freon leaks early can save you from costly repairs and ensure that your AC unit operates efficiently, keeping you cool and comfortable all summer long.

Signs That Your Ac Unit Needs A Freon Refill

Ensuring your AC unit is running efficiently is essential for maintaining a cool and comfortable living space during the hot summer months. One of the key factors in maintaining optimal AC performance is to ensure that the refrigerant, commonly known as Freon, is at the correct level. Freon is responsible for absorbing heat from the air inside your home and releasing it outside. Over time, your AC unit may require a Freon refill, and it’s important to recognize the signs that indicate this need. By being aware of these signs, you can address the issue promptly and ensure your AC unit performs at its best. Let’s explore the signs that indicate your AC unit is in need of a Freon refill.

Decreased Cooling Efficiency

One of the most noticeable signs that your AC unit may require a Freon refill is a noticeable decrease in cooling efficiency. If you find that your home is not as cool as it used to be or that the AC system takes longer to reach the desired temperature, it could be an indication of low Freon levels. Freon is crucial for the heat transfer process within your AC unit, and when it is depleted, the cooling efficiency is significantly affected. To restore the cooling power of your AC unit, a Freon refill may be necessary.

Frost on the Coils

Another indicator that your AC unit needs a Freon refill is the presence of frost on the coils. The evaporator coils in your AC system are responsible for cooling the air that flows through them. When the system is low on Freon, the coils can become too cold, causing moisture from the air to freeze on their surface. If you notice frost or ice buildup on the coils, it is a telltale sign that your AC unit is struggling to maintain the correct level of refrigerant. A Freon refill will help restore the proper balance and prevent further frost buildup.

Unusual Hissing Sounds

An additional sign that your AC unit may require a Freon refill is the presence of unusual hissing sounds. If you hear a hissing noise coming from your AC system, it could be a sign of a refrigerant leak. Freon leaks can occur due to wear and tear, age, or damage to the AC components. When the refrigerant leaks, the pressure in the system decreases, which can result in reduced cooling performance. If you suspect a refrigerant leak, it is crucial to address it promptly and schedule a Freon refill to avoid further damage to your AC unit.

If you come across any of these signs – decreased cooling efficiency, frost on the coils, or unusual hissing sounds – it’s important to consider a Freon refill. While these signs may indicate other issues with your AC unit, it is always best to consult a professional HVAC technician to accurately diagnose the problem and provide appropriate solutions. Remember, addressing these signs promptly will help maintain the efficiency and longevity of your AC unit, ensuring a comfortable and cool indoor environment.

Step-By-Step Guide To Installing Freon In Your AC Unit

Before refilling your AC unit with Freon, it’s important to properly prepare the unit to ensure a smooth installation

process. Follow these steps:

- Turn off the power to your AC unit from the circuit breaker to prevent any accidents.

- Clean the external surface of the unit to remove any dirt or debris that may obstruct the access ports.

- Put on protective gloves and safety glasses to avoid any direct contact with Freon.

- Ensure there are no leaks or damages in the AC unit that may cause problems later on.

The access ports on your AC unit are where you will connect the refrigerant cylinder to refill the Freon. Follow these

steps to locate them:

- Refer to the AC unit manufacturer’s manual to find the exact location of the access ports.

- Usually, the low-pressure port is located near the evaporator coil, while the high-pressure port is found near the

condenser coil. - Wear a flashlight if needed to locate these ports as they can sometimes be tucked away or hidden.

- Keep in mind that different AC unit models may have different access port locations, so consult the manual for

accurate information.

Once you have located the access ports, it’s time to connect the refrigerant cylinder and begin the refilling process:

| Step | Action |

|---|---|

| 1 | Ensure the refrigerant cylinder is upright and that the valve is tightly closed before connecting it. |

| 2 | Attach the charging hose to the cylinder by twisting it on securely. |

| 3 | Connect the other end of the charging hose to the low-pressure access port on the AC unit. |

| 4 | Tighten the connection by twisting it in a clockwise direction. |

| 5 | Slowly open the valve on the refrigerant cylinder to allow the Freon to flow into the AC unit. |

As you refill the Freon, it’s crucial to monitor the pressure levels to ensure they are within the recommended range.

Follow these steps:

- Use a pressure gauge to measure the pressure levels in the AC unit.

- Refer to the AC unit manufacturer’s guidelines to determine the optimal pressure range.

- Slowly add Freon while monitoring the pressure levels until they reach the recommended range.

- Be careful not to overfill the AC unit as this can lead to efficiency issues or even damage the system.

By following these step-by-step instructions, you can successfully install Freon in your AC unit. Remember to always

prioritize safety and consult the AC unit manufacturer’s guidelines for specific instructions relating to your

particular model.

Preparing The AC unit For Refilling

Before refilling the AC unit with Freon, it is important to prepare the unit properly. This involves shutting off the power supply and removing any debris or dust that may have accumulated in the unit. Taking these steps will ensure a smooth and successful refill process, improving the overall performance of your AC unit.

Shutting off the Power Supply

The first step in preparing your AC unit for refilling is to shut off the power supply. This is crucial for your safety as well as to prevent any electrical damage during the refill process. Here’s how to do it:

- Locate the electrical panel or circuit breaker box in your home.

- Identify the circuit breaker for your AC unit. It is typically labeled as “AC” or “Air Conditioner”.

- Flip the circuit breaker switch to the “off” position.

- Double-check that the power is truly off by testing the AC unit and ensuring that it does not turn on.

Removing Debris and Dust from the Unit

Once you have shut off the power supply, the next step is to remove any debris or dust that may be present in the AC unit. This is important as it can hinder the proper functioning of the unit and affect the cooling performance. Follow these steps to remove debris and dust:

- Begin by visually inspecting the exterior of the AC unit for any obstructions or debris.

- If there are any leaves, twigs, or other large debris, use gloves to carefully remove them from the unit.

- Next, open the access panel on the AC unit. Refer to the manufacturer’s instructions if you are unsure how to do this.

- Using a soft brush or cloth, gently remove any dust or dirt from the internal components of the unit.

- If there are any stubborn deposits, lightly spray water or a mild cleaning solution to loosen them, and then wipe them away.

- Make sure to clean the condenser coil and the fan blades thoroughly, as these are areas where dust tends to accumulate.

- Once you have removed all the debris and dust, close the access panel securely.

By shutting off the power supply and removing debris and dust, you have now prepared your AC unit for the refilling process. These steps ensure that the unit will function optimally after the Freon has been refilled, allowing for efficient and effective cooling in your home.

Locating The Access Ports

Before you can start the process of installing freon in your AC unit, it is crucial to locate the access ports. These ports provide you with a way to connect the freon canister and regulate the pressure within the system. In this section, we will walk you through how to identify the high and low-pressure ports, as well as understand the function of each port.

Identifying the High and Low-Pressure Ports

To begin with, it is essential to identify the high and low-pressure ports on your AC unit. These ports serve different purposes in the freon installation process. Let’s take a closer look at how to identify each:

| Port | Location |

|---|---|

| High-Pressure Port | The high-pressure port is typically located on the smaller diameter refrigerant line. |

| Low-Pressure Port | The low-pressure port, on the other hand, is usually situated on the larger diameter refrigerant line. |

Keep in mind that the exact location of these ports may vary depending on the make and model of your AC unit. It is always recommended to consult the manufacturer’s manual or consult a professional if you are unsure about the location.

Understanding the Function of Each Port

Now that you have identified the high and low-pressure ports let’s delve into the function of each. Understanding the role of these ports will help you carry out the freon installation process more effectively and efficiently.

The high-pressure port is where you will connect the pressure gauge and the freon canister. This port allows the freon to flow into the AC system under high pressure. It is crucial to ensure a secure connection to prevent any leaks during the installation process.

The low-pressure port, on the other hand, is responsible for regulating the pressure within the AC system. It acts as the entry point for the freon to flow back into the unit. During the installation process, it is essential to monitor the pressure gauge and ensure the freon is being injected into the system at the correct pressure.

Now that you have a better understanding of the function of each port, you are ready to move on to the next step in the freon installation process: connecting the pressure gauge and the freon canister to the high-pressure port. Stay tuned for our next section, where we will guide you through this step in detail!

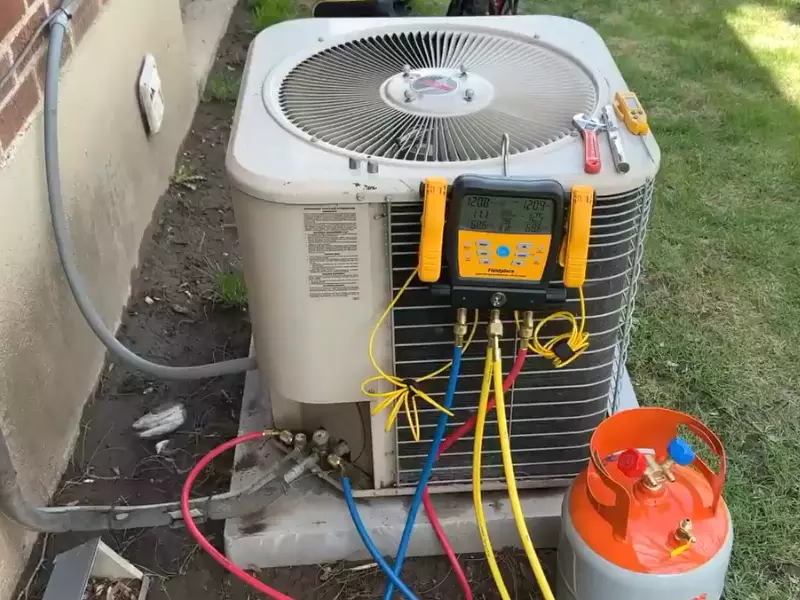

Connecting The Refrigerant Cylinder

When it comes to installing Freon in your AC unit, one of the crucial steps is connecting the refrigerant cylinder correctly. This ensures a smooth and efficient process that will help your AC unit function optimally. To successfully connect the refrigerant cylinder, follow these steps:

Attaching the Correct Hoses to the Cylinder and AC Unit Ports

The first step in connecting the refrigerant cylinder is to attach the correct hoses to the cylinder and AC unit ports. Make sure you have the right hoses that are compatible with the type of refrigerant you are using. Using mismatched hoses can lead to leaks and damage to your AC unit. Refer to the manufacturer’s instructions or consult with a professional to ensure you have the right hoses.

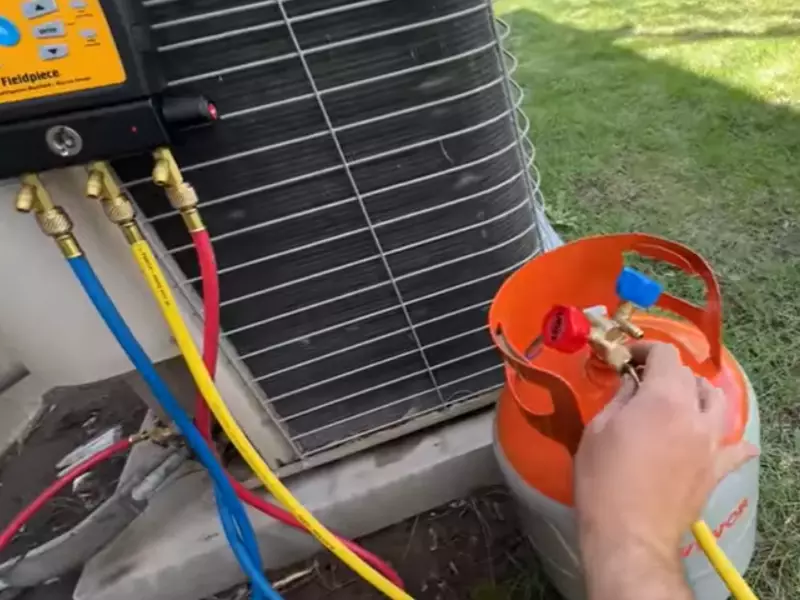

Next, locate the cylinder’s valve and remove the plastic cap. Attach one end of the hose to the valve tightly. Use an adjustable wrench to ensure a secure connection. Make sure the valve is in the closed position before connecting the hose.

Once the hose is securely attached to the cylinder, locate the low-pressure port on your AC unit. Remember, the low-pressure port is different from the high-pressure port, so make sure to identify the correct one. Remove the plastic cap from the low-pressure port, and connect the other end of the hose to it. Again, use an adjustable wrench for a tight and secure connection.

Avoiding Common Connection Mistakes

While connecting the refrigerant cylinder, it is important to avoid common connection mistakes that can lead to leaks and other issues. Here are some tips to help you connect the cylinder correctly:

- Ensure all connections are tight and secure. Use an adjustable wrench to tighten the fittings, but be careful not to overtighten as it can damage the threads.

- Inspect the hoses for any signs of wear or damage before connecting them. Replace any damaged hoses to prevent leaks.

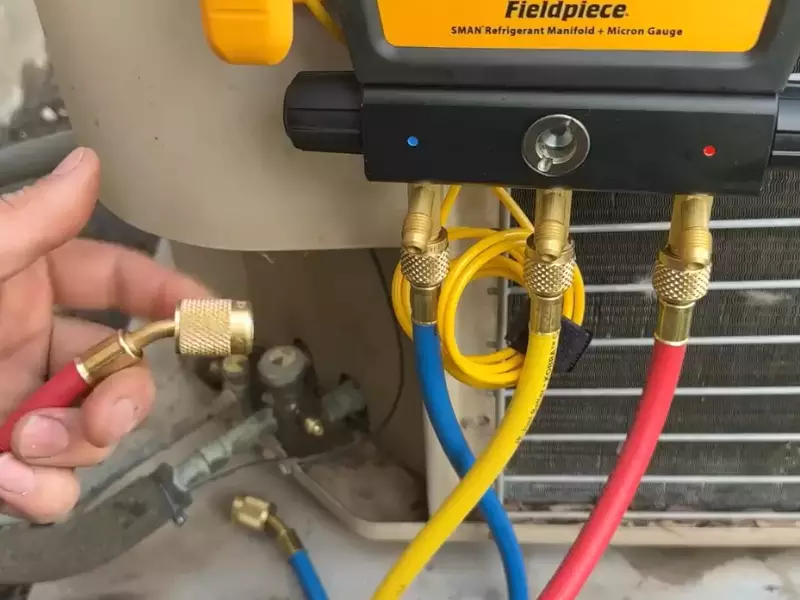

- Use a refrigerant manifold gauge set to monitor the pressure and ensure it stays within the recommended range. This will help you identify any potential issues during the installation process.

- Never connect the refrigerant cylinder directly to the AC unit without using hoses. This can cause damage to the unit and result in refrigerant leaks.

By following these guidelines and avoiding common connection mistakes, you can ensure a safe and successful installation of Freon in your AC unit. Remember to always refer to the manufacturer’s instructions and seek professional assistance if needed.

Monitoring The Pressure Levels

Using a Pressure Gauge to Measure the Levels

Monitoring the pressure levels of your AC unit is a crucial step in the process of installing Freon. It helps ensure that the system is functioning optimally and provides efficient cooling for your space. One of the key tools you’ll need for this task is a pressure gauge.

A pressure gauge is a device that measures the pressure within the AC unit. It consists of a dial or digital display that indicates the pressure readings in PSI (pounds per square inch) or bar. By connecting the pressure gauge to the designated port on the AC unit, you can accurately assess the pressure levels and make necessary adjustments.

To use a pressure gauge, follow these simple steps:

- Locate the low-pressure port on your AC unit. It is usually marked with an “L” or the word “Low”. This port connects to the suction line, which carries refrigerant.

- Remove the cap from the low-pressure port and attach the pressure gauge by screwing it onto the port. Ensure a tight seal to prevent any air leakage.

- Once the pressure gauge is securely attached, turn on your AC unit and let it run for a few minutes to stabilize the system.

- Observe the pressure reading on the gauge. It should fall within the recommended range specified by the manufacturer. This range may vary depending on the specific AC unit model.

- If the pressure reading is too low, it indicates a possible refrigerant leak or insufficient Freon. In this case, it is advisable to seek professional assistance to identify and resolve the issue.

- Conversely, if the pressure reading is too high, it may indicate an overcharge of refrigerant. This can strain the AC unit and reduce its efficiency. Adjustments should be made to bring the pressure back to the optimal range.

- Regularly monitor the pressure levels of your AC unit to ensure its smooth operation. Doing so will help maintain comfortable indoor temperatures and extend the lifespan of your cooling system.

Ensuring Proper Pressure for Efficient Cooling

Proper pressure is essential for efficient cooling and the longevity of your AC unit. When the pressure levels are balanced, the refrigerant can effectively absorb heat from the indoor air, providing a refreshing and comfortable environment. Here are a few tips to ensure proper pressure:

- Regularly check the pressure levels using a pressure gauge, especially before and after adding Freon to your AC unit.

- Refer to the manufacturer’s guidelines or consult with a professional to determine the optimal pressure range for your specific AC unit model.

- If the pressure readings are consistently outside the recommended range, it may indicate a potential issue that requires professional attention. Contact an HVAC technician to diagnose and fix the problem.

- Avoid overcharging or undercharging the refrigerant. Both scenarios can affect the efficiency of your AC unit and lead to costly repairs.

- Consider scheduling regular maintenance with a licensed professional to ensure your AC unit’s pressure levels are consistently monitored and adjusted as needed.

- By maintaining proper pressure levels, you can maximize the cooling performance of your AC unit and enjoy a comfortable living or working space throughout the year.

Safety Precautions To Follow While Installing Freon

When it comes to installing Freon in your AC unit, it is crucial to prioritize safety to avoid any potential hazards. By following a few simple safety precautions, you can ensure that the installation process is not only successful but also safe for yourself and those around you. Let’s dive into the three key safety measures that you should adhere to: wearing protective gear, ensuring proper ventilation in the workspace, and handling R-22 and R-410A safely.

Wearing Protective Gear

Before you start installing Freon in your AC unit, it is imperative to wear the appropriate protective gear. This includes safety goggles, gloves, and a face mask. Safety goggles will protect your eyes from potential splashes or leaks, and gloves will shield your hands from any harmful contact with the refrigerant. A face mask will help prevent inhalation of any harmful fumes. Remember, safety should never be compromised, so make sure you have all the necessary protective gear.

Proper Ventilation in the Workspace

Installing Freon in your AC unit involves working with chemicals that can emit toxic fumes. Therefore, it is crucial to ensure proper ventilation in your workspace to prevent the accumulation of harmful gases. If possible, work in a well-ventilated area with open windows or doors. If that is not feasible, consider using fans or portable ventilation units to keep the air circulating. Proper ventilation will help minimize the risk of exposure to potentially dangerous fumes.

Handling R-22 and R-410A Safely

When handling refrigerants such as R-22 and R-410A, it is essential to follow the necessary safety guidelines. These refrigerants can be harmful if not handled properly. Ensure that you have a thorough understanding of the specific properties and handling procedures for the refrigerant you are using. Take extra care to avoid any accidental spills or leaks, as these substances can cause skin irritation or respiratory issues. When storing refrigerants, ensure they are in sealed containers and kept in a cool and well-ventilated area.

By wearing protective gear, ensuring proper ventilation in your workspace, and handling refrigerants safely, you can significantly reduce the risks associated with installing Freon in your AC unit. Prioritizing safety not only protects you and those around you, but it also contributes to a successful and efficient installation process.

Freon Alternatives: Exploring Environmentally Friendly Options

When it comes to maintaining our AC units, it is essential to stay updated with the latest environmentally friendly options. In this section, we will explore various alternatives to Freon and gain a better understanding of their environmental impact. Let’s take a closer look at the different alternative refrigerants available for AC units.

Understanding the Environmental Impact of Freon

Before we delve into the alternatives, it’s crucial to comprehend the environmental impact of Freon, which is gradually being phased out of usage due to its harmful effects. Freon belongs to a class of compounds known as chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs), both of which are harmful to the ozone layer. These compounds have been directly linked to ozone depletion, contributing to the formation of the ozone hole.

By understanding the detrimental environmental consequences of Freon, we can make informed choices and transition to more sustainable refrigerants for our AC units. Let’s now explore some alternative refrigerants that are more environmentally friendly.

Alternative Refrigerants for AC Units

In recent years, several alternative refrigerants have emerged as viable replacements for Freon. These alternatives are designed to have minimal impact on the ozone layer and reduce overall greenhouse gas emissions. Let’s take a look at some of these environmentally friendly options:

- Hydrofluorocarbons (HFCs): HFCs, such as R-410A and R-32, have gained popularity as Freon substitutes. These refrigerants do not contain chlorine, making them ozone-friendly. While they still have a high global warming potential, they are significantly less harmful to the environment than their predecessors.

- Hydrofluoroolefins (HFOs): HFOs, like R-1234yf and R-1234ze, are a newer generation of refrigerants that offer an even more environmentally friendly alternative to Freon. These compounds have a significantly lower global warming potential and zero ozone-depletion potential, making them highly sustainable choices for AC units.

- Natural Refrigerants: Natural refrigerants, such as ammonia (R-717), carbon dioxide (R-744), and hydrocarbons (R-290, R-600a), have been used for decades due to their excellent thermodynamic properties and low environmental impact. These refrigerants have zero ozone depletion potential and extremely low global warming potential, making them the most eco-friendly options available.

Before making the switch to an alternative refrigerant, it’s important to consult with a licensed HVAC professional who can assess your specific AC unit and ensure compatibility with the chosen refrigerant. They can also guide you through the necessary installation procedures and any safety considerations.

Understanding The Environmental Impact Of Freon

In today’s world, where environmental awareness is on the rise, it is important for us to understand the impact of the products and substances we use. One such substance that has garnered attention is Freon, a commonly used refrigerant in air conditioning units. While Freon plays a crucial role in cooling our spaces, it also has significant environmental implications.

In this article, we will explore the environmental impact of Freon, highlighting its contribution to ozone layer depletion and greenhouse gas emissions.

The Ozone Layer Depletion

Freon is a group of chemicals known as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). These chemicals are long-lived in the atmosphere and have the potential to reach the stratosphere, where they can interact with ozone molecules. The ozone layer acts as a shield, protecting the Earth from harmful ultraviolet (UV) radiation. However, when Freon molecules reach the stratosphere, they release chlorine atoms, which can catalytically destroy ozone molecules. This depletion of the ozone layer can have harmful effects on human health and ecosystems.

Contribution to Greenhouse Gas Emissions

In addition to ozone layer depletion, Freon also contributes to the issue of greenhouse gas emissions. Greenhouse gases trap heat in the Earth’s atmosphere, leading to a rise in global temperatures and climate change. Freon is known to have a high global warming potential (GWP), meaning it has a much stronger warming effect than carbon dioxide, the most well-known greenhouse gas. The release of Freon during the installation or maintenance of an air conditioning unit can therefore contribute to the overall greenhouse gas emissions and exacerbate the effects of climate change.

To put it into perspective, consider the following comparison:

| Substance | GWP |

|—————-|—————————-|

| Carbon Dioxide | 1 (baseline) |

| Freon | 1,760 to 14,800 (varying) |

This table clearly illustrates the significantly higher warming potential of Freon compared to carbon dioxide.

In conclusion, it is crucial for us to understand the environmental impact of Freon. The depletion of the ozone layer and its contribution to greenhouse gas emissions are two significant concerns associated with this commonly used refrigerant. By being aware of these impacts, we can make informed choices about the refrigerants used in our air conditioning units, opting for more environmentally friendly alternatives that minimize harm to the ozone layer and mitigate climate change effects. Remember, as individuals, we have the power to make a difference in preserving the environment for future generations.

Alternative Refrigerants For AC Units

When it comes to refrigerants for AC units, there are several alternatives to traditional freon that are gaining popularity due to their eco-friendliness and energy efficiency. These alternative refrigerants offer a greener solution for cooling your space while meeting regulatory requirements. In this article, we will explore three such alternative refrigerants: R-32, R-410A, and HFO-1234yf.

R-32

R-32 is a promising alternative refrigerant that has gained attention for its lower global warming potential (GWP) compared to traditional freon. It offers improved energy efficiency, which means it not only cools your space effectively but also reduces your energy consumption, leading to cost savings in the long run. R-32 also has a low environmental impact, making it a sustainable choice for AC units. It is important to note that R-32 is flammable and needs to be handled with caution during installation and maintenance.

R-410A

R-410A is another popular alternative refrigerant that has become widely accepted as a replacement for freon in AC units. It boasts a higher cooling capacity and better energy efficiency than traditional refrigerants, resulting in improved performance and reduced electricity consumption. R-410A is not ozone-depleting and has a lower GWP, making it an environmentally friendly choice. However, it is crucial to ensure that your AC unit is compatible with R-410A before considering a retrofit or replacement.

HFO-1234yf

HFO-1234yf is a newer alternative refrigerant that is gaining traction due to its extremely low GWP. It is considered one of the most environmentally friendly refrigerants available. HFO-1234yf offers similar cooling performance to traditional refrigerants while significantly reducing the impact on global warming. Additionally, it has a minimal effect on air quality, making it a safe choice for both residential and commercial AC units. However, as it is a relatively new refrigerant, it may not be readily available or compatible with all AC units, and professional assistance is recommended for installation.

Frequently Asked Questions For How To Install Freon In Ac Unit

Can I Add Freon To My AC unit Myself?

No, you should not add Freon to your AC unit yourself. It is best to hire a professional to handle this task.

How Much Does It Cost To Add Freon To AC Unit?

Adding Freon to an AC unit can cost around $150 to $300. The exact cost may vary depending on factors like the size of the unit, the type of refrigerant required, and the technician’s fees. It’s best to contact a professional HVAC technician for an accurate estimate.

How Do I Know If My AC is Low On Freon?

To determine if your AC is low on Freon, check for these signs: weak airflow, warm air coming from vents, ice buildup on the evaporator coil, and unusual noises. If you notice any of these issues, it’s best to contact a professional HVAC technician for Freon refill or system inspection.

How Do I Add Freon To My AC wall Unit?

To add Freon to your AC wall unit, follow these steps:

1. Turn off the unit and unplug it.

2. Locate the service valves on the refrigerant lines.

3. Connect the refrigerant canister to the low-pressure service valve.

4. Slowly release the Freon into the system, monitoring the pressure.

5. Disconnect the canister and close the service valves.

Note: It’s best to consult a professional for this task to ensure proper handling and avoid any harm to yourself or the unit.

Conclusion

Installing Freon in an AC unit may seem challenging, but with proper guidance, it can be accomplished easily. By following the step-by-step instructions provided in this blog post, you can ensure the smooth functioning of your AC unit and enjoy the comfort it provides.

Remember to prioritize safety and consult a professional if you encounter any difficulties. With the right knowledge and precautions, maintaining your AC unit’s Freon levels can save you from unnecessary expenses and keep your home cool during the hot summer months.