To install a flexible gas line, first turn off the gas supply, remove the old gas line, attach the new gas line using fittings, and check for leaks using soapy water. Flexible gas lines are a flexible and convenient option for connecting gas appliances to the main gas supply.

They offer flexibility in installation and can be easily bent and maneuvered around obstacles. In this guide, we will provide you with step-by-step instructions on how to properly install a flexible gas line. By following these instructions carefully, you can ensure a safe and reliable gas connection for your appliances.

Remember to always prioritize safety and follow the manufacturer’s guidelines for your specific gas line and appliance.

Understanding Flexible Gas Lines

Benefits of using flexible gas lines

When it comes to installing gas lines in your home, using flexible gas lines can offer several benefits. These innovative piping systems are designed to provide increased convenience, safety, and flexibility. Here are some key advantages of using flexible gas lines:

- Easy installation: Flexible gas lines are much easier to install compared to traditional rigid pipes. They can be easily bent and maneuvered around obstacles, making the installation process faster and more efficient.

- Improved safety: Flexible gas lines are constructed with durable materials that make them resistant to corrosion and leaks. Additionally, they are equipped with safety features such as fittings that provide a secure connection, reducing the risk of gas leaks.

- Flexibility: As the name suggests, flexible gas lines can be easily bent and adjusted to fit the layout of your home. This allows for more flexibility during installation, especially in tight spaces or when dealing with complex plumbing configurations.

- Cost-effective: Flexible gas lines are often more cost-effective compared to rigid pipes. Not only are they typically cheaper to purchase, but their easy installation process can save you money on labor costs as well.

Types of flexible gas lines

Before installing a flexible gas line, it’s important to understand the different types available. Here are two common types of flexible gas lines:

| Type | Description |

|---|---|

| Corrugated stainless steel tubing (CSST) | CSST is a flexible tube made of stainless steel that is coated with a polymer jacket. This type of gas line is commonly used for residential applications due to its durability and flexibility. |

| Polyethylene (PE) gas pipe | PE gas pipe is a flexible plastic pipe that is commonly used for underground applications. It is resistant to corrosion and provides excellent flexibility, making it suitable for a wide range of installations. |

Overview of the installation process

Installing a flexible gas line requires careful planning and adherence to safety guidelines. Here is a brief overview of the installation process:

- Prepare the area: Before installation, ensure that the area is clean and free from any obstructions. Remove any old gas pipes or fittings that may interfere with the installation.

- Measure and cut: Measure the length of the flexible gas line needed and use a pipe cutter to make a clean cut. Avoid using sharp tools or excessive force that may damage the pipe.

- Connect fittings: Attach the appropriate fittings to the ends of the flexible gas line. Ensure that the fittings are securely tightened to prevent gas leaks.

- Secure the line: Use appropriate clamps or brackets to secure the flexible gas line in place. This will prevent it from moving or being accidentally damaged.

- Test for leaks: After installation, conduct a thorough leak test to ensure the integrity of the gas line. Apply a solution of soapy water to the fittings and connections and check for any bubbles, which indicate gas leaks.

- Final checks: Once the installation is complete and there are no leaks, make sure to inspect the entire system for any potential issues. Double-check that all connections are secure and properly installed.

With proper understanding, flexible gas lines offer numerous benefits and can be installed safely and efficiently. However, it is important to consult with a professional or adhere to local building codes and regulations to ensure a successful installation.

Preparing For Installation

Before you begin installing a flexible gas line, it’s important to adequately prepare. This involves gathering the necessary tools and materials, measuring and planning the gas line route, and taking safety precautions to ensure a smooth and safe installation process.

Gathering the necessary tools and materials

To ensure a successful installation, it’s crucial to have the right tools and materials on hand. Here are the essentials you’ll need:

- Flexible gas line

- Gas shut-off valve

- Pipe wrench

- Teflon tape

- Gas leak detector solution

- Measuring tape

- Marker

- Hacksaw or pipe cutter

- Fittings and connectors

- Adjustable wrench

Measuring and planning the gas line route

Before beginning the installation, it’s important to measure and plan the route for your flexible gas line. Consider the location of your gas appliances and the most efficient route to connect them. Here’s how you can do it:

- Measure the distance between your gas appliance and the gas supply line.

- Decide on the route the flexible gas line will take, ensuring it is free from obstacles and not in contact with sharp edges.

- Use a marker to mark the location of the gas line on the walls or floor, making it easier to follow during the installation process.

Safety precautions to take before installation

Before you start installing a flexible gas line, it’s vital to prioritize safety. Taking the following precautions will help prevent accidents and ensure a secure installation:

- Always turn off the gas supply at the main shut-off valve before beginning any work.

- Check for leaks in your existing gas line using a gas leak detector solution. If any leaks are detected, it’s crucial to address them before proceeding with the installation.

- Ensure proper ventilation in the area where the installation will take place to prevent the buildup of gas.

- Wear safety goggles and gloves to protect yourself during the installation.

- Keep flammable materials away from the installation area.

By following these steps and taking the necessary precautions, you’ll be well-prepared to install a flexible gas line safely and efficiently. Remember to always consult a professional if you have any doubts or concerns during the installation process.

Step-By-Step Installation Guide

Installing a flexible gas line can be a convenient and efficient option for connecting your appliances to the gas supply. With the right tools and careful steps, you can easily install a flexible gas line in your home. In this step-by-step guide, we will walk you through the process, from shutting off the gas supply to testing for leaks and ensuring proper connections.

Shutting off the gas supply

Before starting any gas line installation project, it is essential to shut off the gas supply to ensure safety. Follow these steps to shut off the gas:

- Locate the gas meter. It is usually found outside your home.

- Turn off the gas by closing the main shut-off valve. It is typically located next to the gas meter.

- Double-check that the gas is turned off by testing gas appliances, ensuring they no longer work.

Disconnecting the old gas line (if applicable)

If you are replacing an old gas line, you will need to disconnect it first. Follow these steps to disconnect the old gas line:

- Inspect the old gas line for any signs of damage or wear.

- Using a pipe wrench, loosen the connection at both ends of the old gas line to disconnect it from the appliances and the gas supply.

- Carefully remove the old gas line and dispose of it properly.

Installing the shut-off valve

Before connecting the flexible gas line, it is essential to install a shut-off valve. This valve allows you to control the gas supply to your appliances. Follow these steps to install the shut-off valve:

- Choose a suitable location for the shut-off valve, typically near the appliance.

- Shut off the gas again at the main shut-off valve.

- Using a pipe cutter, cut the existing gas line where you want to install the shut-off valve.

- Attach the shut-off valve to both ends of the cut gas line using flared fittings and a wrench.

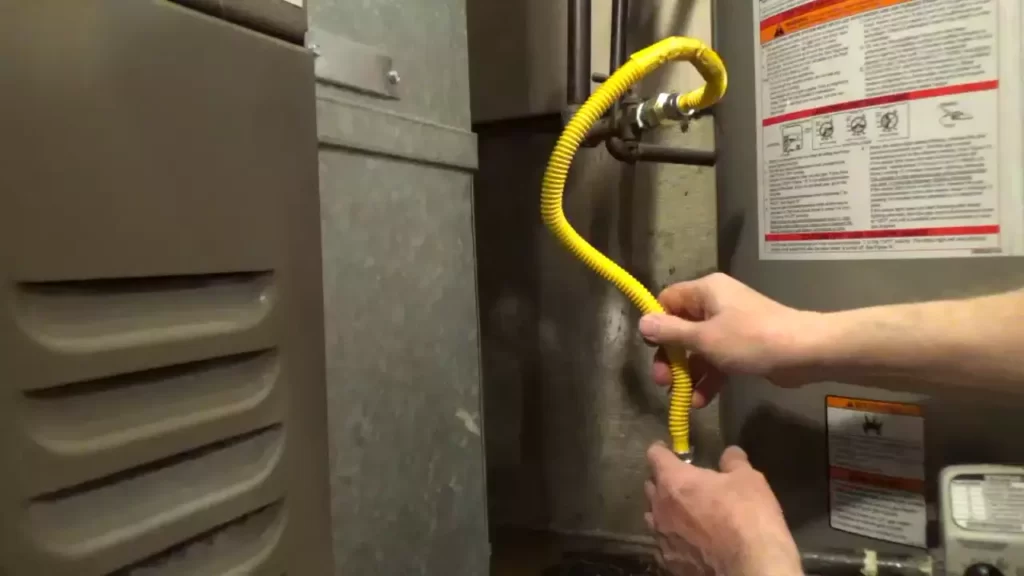

Connecting the flexible gas line to the shut-off valve and appliances

Now that the shut-off valve is installed, it’s time to connect the flexible gas line to the shut-off valve and your appliances. Follow these steps:

- Measure and cut the flexible gas line to the desired length, leaving some extra length for flexibility.

- Attach one end of the flexible gas line to the shut-off valve with a flared fitting and a wrench.

- Attach the other end of the flexible gas line to the appliance using the appropriate connector and a wrench.

Testing for leaks and ensuring proper connections

After the installation is complete, it is crucial to test for leaks and ensure all connections are secure. Follow these steps for a safe and leak-free installation:

- Use a gas leak detector or soapy water to check for any leaks at the connections.

- If you detect a leak, tighten the connections further or replace any faulty parts.

- Once all connections are secure, open the main shut-off valve and test the appliances to ensure they are functioning properly.

Installing a flexible gas line may seem daunting at first, but by following this step-by-step guide and taking necessary safety precautions, you can have a successful installation. Remember to consult a professional if you are unsure or uncomfortable with any step of the process. With a reliable and efficient gas line, you can enjoy the benefits of gas-powered appliances in your home.

Tips For A Successful Installation

Properly Securing and Supporting the Flexible Gas Line

One of the most important aspects of installing a flexible gas line is ensuring that it is properly secured and supported. This not only ensures the safety of your installation but also helps prevent any leaks or damage. To properly secure a flexible gas line, you should:

- Use appropriate brackets or clamps to hold the line in place at regular intervals.

- Make sure the brackets or clamps are securely fastened to a solid surface, such as a wall or floor.

- Avoid sharp corners or bends that could stress and damage the line.

Using the Correct Fittings and Adapters

Choosing the correct fittings and adapters for your flexible gas line is vital to ensure a successful installation. The following tips will help:

- Measure the diameter of the gas line correctly to ensure you select the appropriate fittings and adapters. Using the wrong size can result in leaks or improper connections.

- Opt for fittings and adapters made of durable materials like brass or stainless steel, as they are less prone to corrosion and offer better longevity.

- Apply pipe thread sealant or gas-rated Teflon tape to the threads of the fittings and adapters to create a tight and secure seal.

Following Local Building Codes and Regulations

Adhering to local building codes and regulations is essential when installing a flexible gas line. Failure to comply with these requirements can lead to serious safety hazards and legal consequences. Here are some tips to ensure compliance:

- Research and familiarize yourself with the specific regulations and codes in your area related to gas line installation.

- Obtain any necessary permits or approvals before starting the installation.

- Consult with a licensed professional or local inspector if you have any doubts or questions regarding compliance.

Considering Professional Help for Complex Installations

While simple gas line installations can often be done by homeowners, more complex installations may require the expertise of a professional. Taking on a complicated installation without the necessary knowledge or experience can lead to dangerous situations. Keep in mind the following:

- If your installation involves multiple bends, connections to multiple appliances, or runs through confined spaces, it may be best to hire a licensed plumber or gas line installation expert.

- Professional installers have the necessary training and equipment to ensure a safe and efficient installation.

- Even if you opt for professional help, it’s still important to understand the basics of gas line installation to communicate effectively with the experts and ensure the work meets your needs.

Maintenance And Safety Guidelines

Proper maintenance and regular inspection of the flexible gas line is vital to ensure the safety of your home and loved ones. Gas leaks can be extremely dangerous, leading to fire hazards and health risks. In this section, we will discuss the importance of maintaining and inspecting your flexible gas line, how to identify signs of gas leaks, and the significance of professional inspection and service. Taking these safety precautions will help keep your home secure and give you peace of mind.

Regular inspection and maintenance of the flexible gas line

To maintain the integrity of the flexible gas line, regular inspections are necessary. We recommend inspecting the line at least once a year, or as per the manufacturer’s guidelines. Here are some maintenance and inspection tasks you can perform:

- Check for any visible damages or signs of wear and tear such as cracks, cuts, or abrasions on the outer protective covering of the flexible gas line. These can compromise its safety and longevity.

- Ensure that the line is properly connected to the gas supply and the appliance it serves. Double-check the fittings and connections for any leaks.

- Inspect the gas line for any twisting, kinking, or bending that could restrict the flow of gas. Make sure it is properly aligned and positioned.

- If you notice any issues during the inspection, promptly address them. Replace any damaged parts or seek professional assistance if necessary.

Signs of gas leaks and how to respond

Gas leaks can be hazardous, so it’s crucial to be aware of the signs and know how to respond. Here are some indicators that may indicate a gas leak:

- A distinct smell of rotten eggs or sulfur in the air

- Hissing or hissing sounds near the gas line or appliance

- Dead or dying plants around the area where the gas line is installed

- Unusually high gas bills

If you suspect a gas leak, follow these immediate steps:

- Do not light any matches or use electrical switches or appliances.

- Evacuate the premises and ensure everyone’s safety. Leave windows and doors open for ventilation while exiting.

- Call your gas provider or emergency services right away. Only trained professionals should handle gas leak emergencies.

- Do not attempt to fix the leak yourself. Leave it to the experts to inspect, repair, and ensure everything is safe before returning to your home.

Importance of professional inspection and service

While regular inspections are essential, professional inspection and service should not be overlooked. Hiring a qualified technician with expertise in handling flexible gas lines can prevent potential hazards and ensure top performance. Here’s why professional inspection and service are significant:

- Professionals possess the necessary knowledge and tools to thoroughly inspect the gas line, identifying any potential issues that may go unnoticed.

- They have the expertise to handle repairs, replacements, or installations safely and according to industry standards.

- Regular servicing by a professional can extend the lifespan of your flexible gas line, reducing the risk of leaks and other complications.

- Professional service providers also keep updated on the latest safety regulations and guidelines, ensuring compliance.

By prioritizing regular inspection, promptly responding to signs of gas leaks, and seeking professional help, you can ensure the safety of your flexible gas line and protect your home and loved ones from potential hazards.

Troubleshooting Common Issues

Common problems during installation and how to address them

While installing a flexible gas line, you may encounter a few common issues. It’s important to be aware of these problems and know how to troubleshoot them effectively. Addressing these issues promptly will ensure that your installation is safe and efficient.

1. Alignment and fitting problems

One of the most common issues during the installation of a flexible gas line is alignment and fitting problems. These problems can occur when the line is not properly aligned with the connectors or if the fittings are not tightened enough.

To address this issue, make sure that you carefully align the line with the connectors and ensure that the fittings are tightened correctly. Use a wrench to tighten the fittings, ensuring a secure and leak-free connection.

2. Pipe damage or kinking

Another problem that may arise during installation is pipe damage or kinking. This can occur if the line is bent too tightly or if it comes into contact with sharp objects.

To avoid pipe damage or kinking, always handle the flexible gas line with care. Avoid bending the line beyond its specified limit and ensure that it is installed in an area where it won’t come into contact with any sharp objects or edges. If you notice any damage or kinks in the line, it’s best to replace it with a new one.

3. Incorrect sizing

Incorrect sizing can also be a common issue during installation. It’s crucial to ensure that the flexible gas line is properly sized to fit your specific needs. Using a line that is either too long or too short can result in inefficient gas flow and potential safety hazards.

To address this issue, carefully measure the distance between the gas source and the appliance you are connecting. Use this measurement to select the appropriate length of the flexible gas line. Make sure to leave a little slack to allow for movement and easy installation.

How to fix gas leaks

A gas leak is a serious issue that requires immediate attention. If you suspect a gas leak, it’s crucial to address it promptly to avoid any potential hazards. Here’s how you can fix a gas leak:

- First, turn off the gas supply to the affected area. Locate the gas shut-off valve near the leak and turn it off.

- Open windows and doors to allow fresh air to circulate and help dissipate any accumulated gas.

- Avoid using any electrical appliances or open flames until the leak is fixed.

- To fix the leak, carefully inspect the flexible gas line for any visible damage or loose connections. If you notice any issues, tighten the fittings or replace damaged parts as necessary.

- After addressing the issue, you can perform a simple gas leak test using a natural gas leak detector or a mixture of soapy water. Apply the detector or soapy water to the connections and observe for any bubbles indicating a leak. If bubbles appear, recheck and tighten the fittings or replace the line if needed.

- If you are unsure or unable to fix the gas leak yourself, it’s recommended to contact a professional plumber or gas technician to assess and repair the issue.

Troubleshooting issues with gas appliances connected to the flexible gas line

Occasionally, you may encounter issues with gas appliances that are connected to a flexible gas line. Here are a few common troubleshooting tips:

- Inadequate gas flow: If you notice that the gas flow to an appliance is weak or inconsistent, check for any obstructions in the line or fittings. Clean or replace the affected components as necessary to ensure proper gas flow.

- Inefficient burner flames: If you observe yellow or uneven burner flames, it may indicate a problem with the gas-to-air ratio. Adjust the air mixture on the appliance according to the manufacturer’s instructions to achieve a blue and even flame.

- Ignition problems: If the appliance has trouble igniting, check the ignition source, such as the pilot light or electronic igniter, and ensure they are functioning correctly. Clean or replace the ignition source if necessary.

- Unusual odors or smells: If you detect unusual odors or smells from the gas appliance, it could indicate a gas leak. Follow the steps mentioned earlier to address and fix any gas leak issues.

By troubleshooting these common issues during installation and addressing them promptly, you can ensure a safe, efficient, and trouble-free experience with your flexible gas line and connected appliances.

Frequently Asked Questions For How To Install Flexible Gas Line

How Far Can I Run Flexible Gas Line?

The maximum distance for running a flexible gas line depends on the type and size of the line. It is generally recommended to consult local codes and regulations, as well as the manufacturer’s instructions, to determine the specific requirements for your situation.

How Do You Seal A Flexible Gas Line?

To seal a flexible gas line, follow these steps:

- Turn off the gas supply to ensure safety.

- Clean the connection with a cloth to remove dirt and debris.

- Apply an approved gas sealant, like Teflon tape or pipe dope, to the threads of the fitting.

- Tighten the fitting using an adjustable wrench until snug.

- Use a leak detection solution to check for any gas leaks before turning the supply back on.

Can I Run a Flexible Gas Line Outside?

Yes, it is possible to run a flexible gas line outside. However, it is important to follow safety guidelines and regulations. Seek professional assistance and ensure the line is properly installed, protected from damage, and meets local building codes. Always prioritize safety when dealing with gas lines.

How Do You Install A Gas Tight Gas Line?

To install a gas tight gas line, follow these guidelines:

- First, ensure the line is approved for gas use and appropriate for the intended application.

- Next, clean the connecting pipes thoroughly and remove any debris or dirt.

- Apply Teflon tape to the threading on the pipes and secure them tightly.

- Test the connections for any leaks using a gas leak detector or soapy water solution.

- If there are no leaks, turn on the gas supply and check for proper functionality. Remember to follow all safety precautions.

Conclusion

Installing a flexible gas line can be a straightforward process when following the necessary steps and precautions. By ensuring proper measurement, using the correct materials, and adhering to safety guidelines, you can successfully install a flexible gas line in your home.

Remember to consult a professional if you are unsure or uncomfortable with any aspect of the installation. With the right knowledge and care, you can easily have a reliable and efficient gas line system.